|

|

|

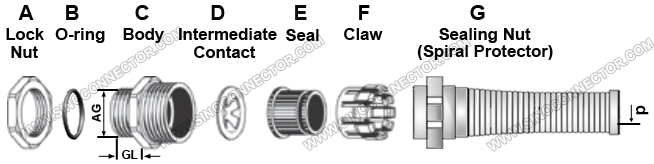

Thread |

Cable Range |

AG |

Panel Mounting Hole |

GL |

H |

d |

Spanner |

|

|

Min.(mm) |

Max.(mm) |

|||||||

|

G1/4" |

3 |

6.5 |

13.157 |

13.1-13.4 |

7 |

53 |

6.8 |

17 |

|

G1/4" |

2 |

5 |

13.157 |

13.1-13.4 |

7 |

53 |

6.8 |

17 |

|

G1/4" |

4 |

8 |

13.157 |

13.1-13.4 |

7 |

66 |

8.2 |

18 |

|

G1/4" |

2 |

6 |

13.157 |

13.1-13.4 |

7 |

66 |

8.2 |

18 |

|

G3/8" |

4 |

8 |

16.662 |

16.6-16.9 |

8 |

66 |

8.2 |

19 |

|

G3/8" |

2 |

6 |

16.662 |

16.6-16.9 |

8 |

66 |

8.2 |

19 |

|

G3/8" |

5 |

10 |

16.662 |

16.6-16.9 |

8 |

77 |

10.3 |

20 |

|

G3/8" |

3 |

7 |

16.662 |

16.6-16.9 |

8 |

77 |

10.3 |

20 |

|

G1/2" |

6 |

12 |

20.955 |

20.9-21.2 |

8 |

88 |

12.3 |

24 |

|

G1/2" |

5 |

9 |

20.955 |

20.9-21.2 |

8 |

88 |

12.3 |

24 |

|

G1/2" |

10 |

14 |

20.955 |

20.9-21.2 |

8 |

98 |

14.3 |

27 |

|

G1/2" |

7 |

12 |

20.955 |

20.9-21.2 |

8 |

98 |

14.3 |

27 |

|

G3/4" |

13 |

18 |

26.441 |

26.4-26.7 |

9 |

111 |

18.4 |

30 |

|

G/3/4" |

9 |

16 |

26.441 |

26.4-26.7 |

9 |

111 |

18.4 |

30 |